Skip to content

- Overview

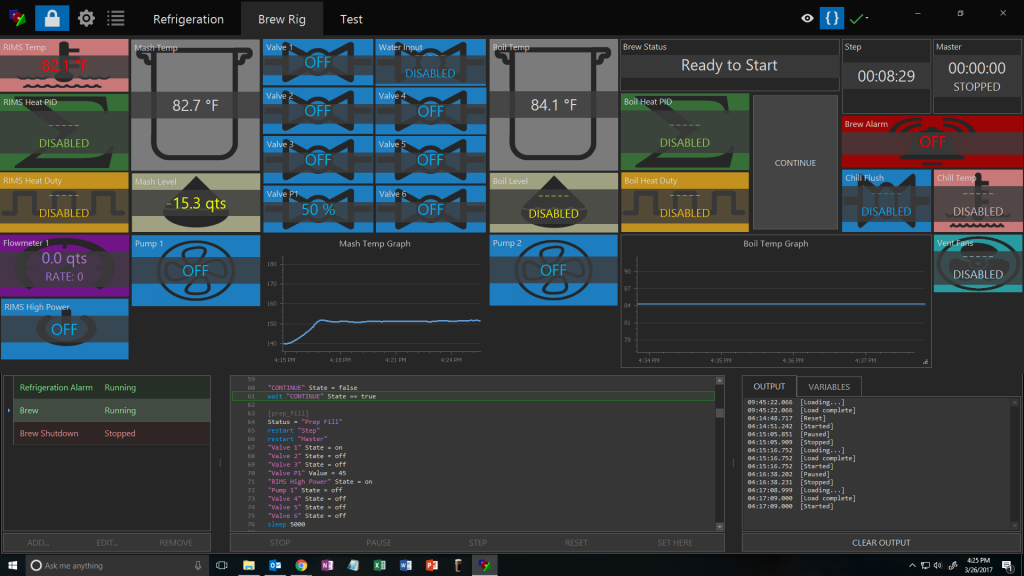

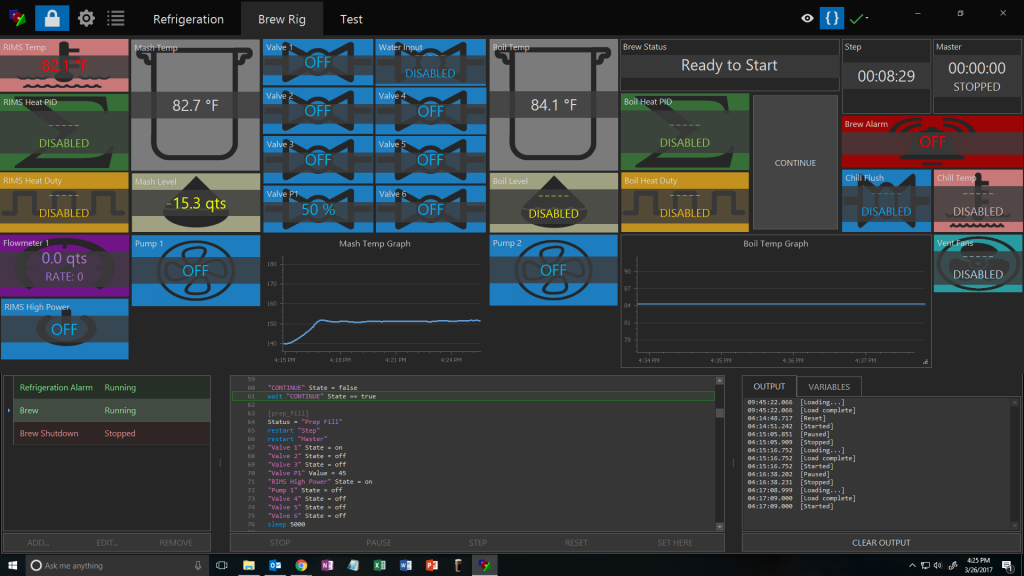

- Software which monitors, controls, automates process machinery such as breweries

- Windows based application with intuitive setup, operation, and user interface

- Touchscreen friendly, customizable graphical interface for setup and operation

- Communicates with one or more local or networked microcontroller interfaces

- Microcontroller interfaces serve as hardware I/O for physical electronic controls

- Simple & flexible script language supports complete automation and multitasking

- Broad set of I/O & algorithms: digital, analog, PWM, counters, PID, duty cycle, hysteresis, temperature, etc.

- Hardware

- Microcontroller interfaces are user provided, readily available boards (Arduino, etc.)

- Requires no programming – interface firmware and upload utility are provided

- Functions offloaded to interfaces for speed and communication failure tolerance

- Flexible, on-demand PIN declarations for integration with different devices

- Digital Outputs

- Digital Inputs

- PWM / Analog Outputs

- Analog Inputs

- High frequency Counter Inputs (total and rate)

- Various Temperature Sensors

- Local LCD Display Output

- Device control algorithms

- Duty Cycle Output

- Hysteresis Output

- PID Output

- Approach Logic

- Multiple device type integrations

- Relays (SSR / mechanical) for power devices such as heaters, motors, etc.

- Contacts, switches, or sensors, like buttons, proximity, float, flow, etc.

- Analog sensor reading, such as pressure, temperature, flow, weight, etc.

- PWM (Pulse Width Modulation) control of motors, lights, heaters, etc.

- Analog output for control of proportional valves, pumps, actuators, etc.

- Temperature measurement via thermistor/analog, RTD, or 1-wire (DS18B20)

- Hall effect/pulse sensors such as encoders, flowmeters, proximity, etc.

- Local LCD displays for information presentation separate from user interface

- Software

- Windows application serving as one unified setup and control environment

- Modern intuitive touch-panel interface with selectable themes

- Small CPU/memory footprint runs on most PC hardware (Raspberry Pi pending)

- Multi-page “Workspaces” for display and control of different machines & systems

- Customizable graphical representation and control of physical devices

- Real-time display, control, and configuration of devices, timers, alarms, buttons

- Continuous device data collection, providing immediate access to historical data

- Flexible graphing of selectable values for historical data presentation/analysis

- Multiple, fully customizable layouts with user selectable images and formatting

- Supports multiple control types per physical device (e.g. Duty Cycle and PID)

- Communicates with multiple local or remote interfaces for unlimited I/O

- Local interfaces connect via USB & remote interfaces via standard TCP network

- Requires no programming for setup or user interface configuration

- Flexible & simple scripting language for process automation / autonomy

- Scripting includes flow control, variable handling, device control, and properties

- Concurrent Scripts to manage different machines systems and perform multi-tasking

- Parameters and calibrations independently configurable for each device

- Layered calibrations including Thermistor, RTD, Offset, Multiplier, Conversions, etc.

- Security system to limit unauthorized changes to environment or device states

- Multiple configurable alarms with hardware activations and email notifications

- Multiple count-up or count-down timers

- Multiple controls for user interaction with the automated control system

- Multiple variables for handling and monitoring data or operation performance

- Multiple buttons or switches for user interaction with automated processes