BruControl is an integrated software and hardware system to monitor, control, log, and automate small scale process machinery. It was designed for breweries, but can be used for many other applications such as food processing, manufacturing, home automation, or industrial control systems.

At the heart of the system is the BruControl software application, which provides a rich, customizable user interface and handles process automation and data logging/reporting for one or more control systems. The application is easy to set up and use, and allows for nearly infinite flexibility to grow from a simple, manual control system to a fully automated, complex concurrent process system.

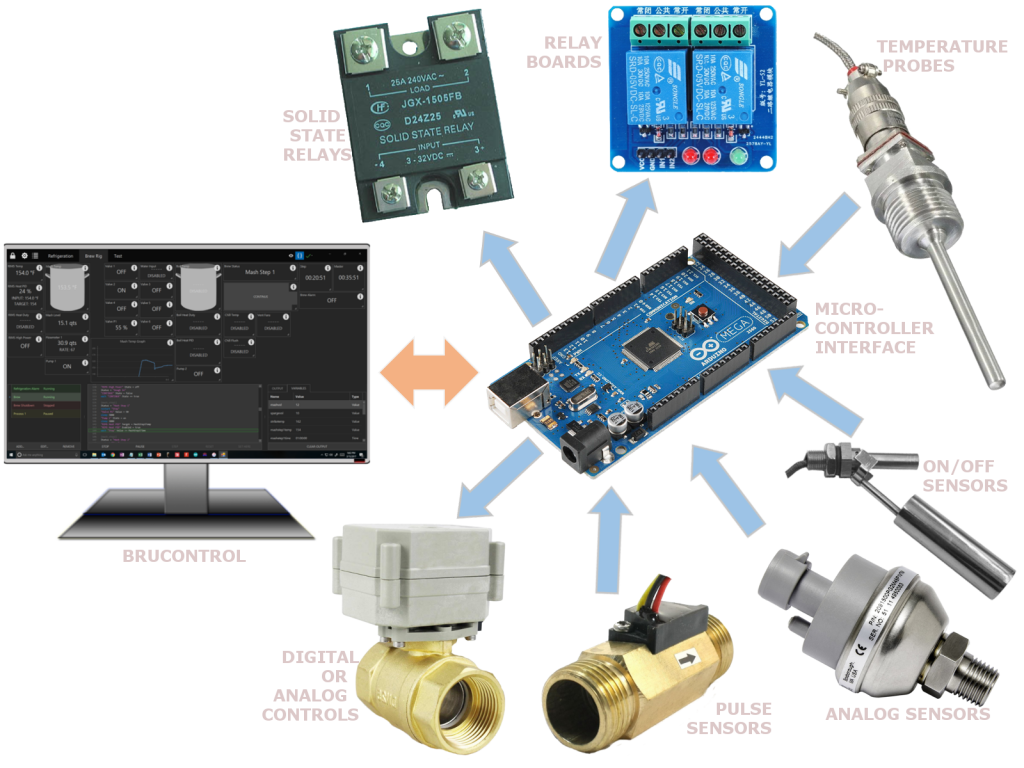

BruControl utilizes readily available, non-proprietary micro-controller boards such as Arduinos to serve as a control system’s physical input and output “interface”. These interfaces can be supplied by the user/builder or sourced from us. BruControl can work with one or more of these interfaces, connected locally via USB or remotely via Ethernet or Wi-Fi network to control multiple machines or systems simultaneously.

BruControl has a touchscreen-friendly user interface which is intuitive and flexible and uses configurable graphical elements to represent physical devices, timers, alarms, graphs, user controls, etc. Systems can be built in stages without the constraints of a dedicated hardware system.

BruControl can be used simply as a digital control panel, replacing physical indicators, switches, and discreet hardware controls, or as a multi-tasking automated logic controller via its rich yet simple script language.

BruControl requires no programming knowledge or additional software installation and supports a broad range of inputs, outputs, and algorithms, including digital, analog, PWM, counter, hysteresis, duty cycle, deadband logic, PID, and special digital devices such as 1-wire and RTD temperature, wireless hydrometers, local LCD displays, and others.